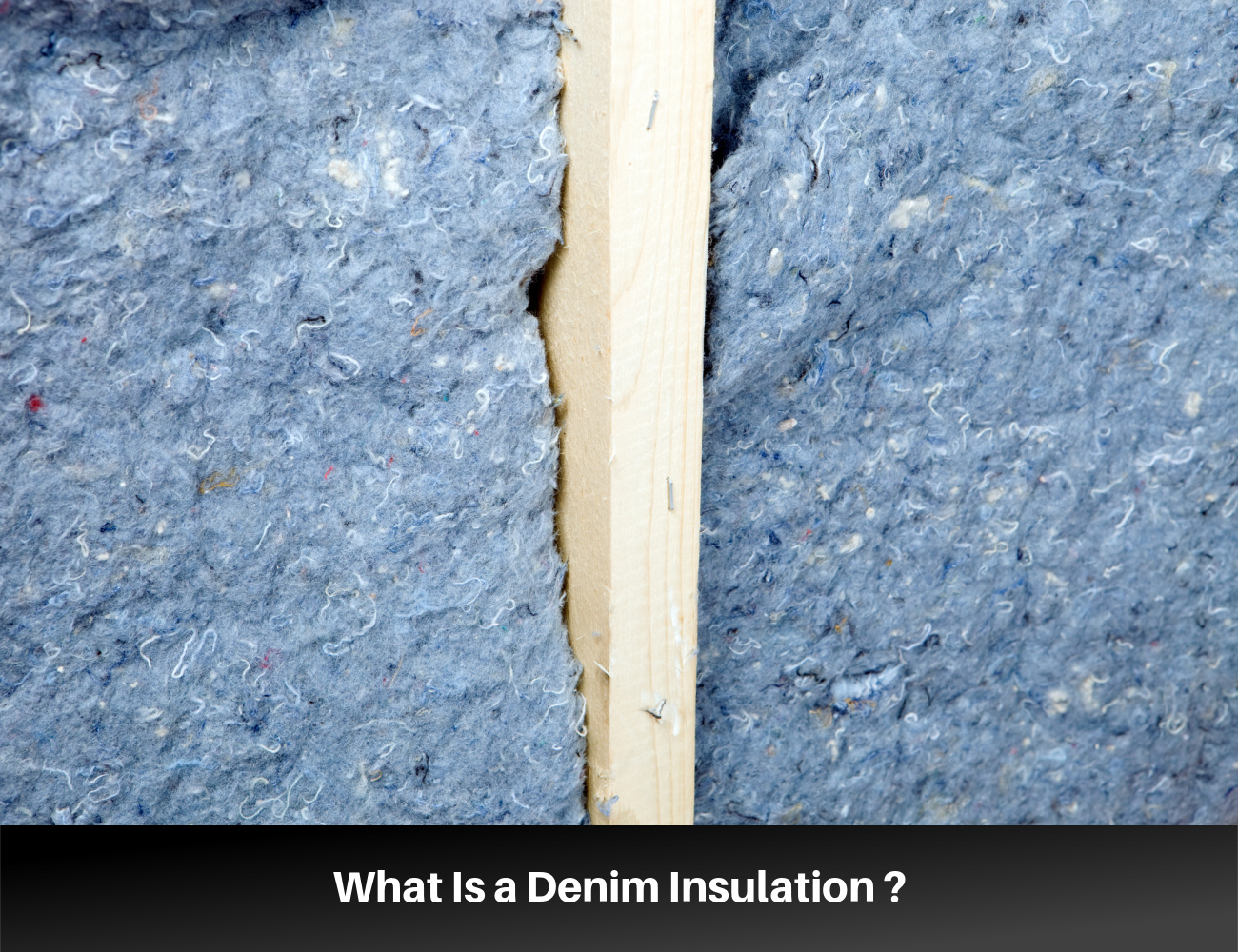

Denim insulation is exactly what it sounds like–old blue jeans recycled into house insulation. Blue jean insulation occupies a small but growing niche in home insulation. It is made from recycled material and can even be recycled again after it has served its purpose. Approximately 500 pairs of recycled blue jeans will completely insulate a new home.

More and more people are trying to replace insulation materials like fiberglass batts and rigid or sprayed foam with more ecologically sound greener products. Denim batt insulation provides that option–at a cost.

How Denim Insulation is Made

Old jeans and other compatible cotton are sent to recycling plants where zippers, buttons, and any contaminants are removed. It is then shredded into small pieces and packed into thousand pound bales.

The bales are taken to another processing plant where the fabric is shredded further. The resulting product is closer to the original state of cotton balls and looks somewhat like blue cotton candy.

Once it arrives at the manufacturing plant it is treated with boric acid to make the material fire retardant and pest, mold, and mildew resistant. It is heated to bond the fibers together and pressed into large mats that are then cut to size.

Denim Insulation Pros

Denim batt insulation has around the same R-value as fiberglass batts–R-3.5 per inch. The batts come in standard sizes to fit standard 2 x 4 and 2 x 6 stud framed walls with R-values ranging from R-10 to R-20.

Denim Insulation is Eco-Friendly

Denim insulation is close to 100% recycled material. The majority of the inputs come from worn blue jeans. The balance of raw materials is off-cuts from clothing manufacturers and recycled material that is compatible with denim.

Denim Batts are Safer to Install

Denim insulation does not contain formaldehyde. It does not contain small fibers that can be breathed in–like fiberglass and mineral wool insulation. There are no Volatile Organic Compounds (VOC) in denim insulation.

Most people can install denim insulation without gloves, masks, or special clothing. It contains no chemicals or irritating fibers. It usually contains a small amount of dust left over from the manufacturing process. Anyone with sensitive skin or breathing problems should take the appropriate precautions.

Denim Insulation is Fire Retardant

Denim insulation is a class A fire retardant. It is treated with boric acid to reduce flame spread. Borate is the same fire retardant product used in cellulose insulation.

Denim Batts are Pest and Mildew Resistant

Boric acid also acts to repel insects and rodents. Borate-treated insulation ensures that insects and rodents will not take up residence in or eat denim batt insulation. Unless denim becomes wet and stays wet for some time the boric acid also restricts mildew and mold growth.

Denim Provides Better Soundproofing

Denim insulation has an STC rating of 52 compared to fiberglass STC of 46. The chart below shows a significant improvement from STC 45 to STC 50. Denim can provide up to 30% more soundproofing than fiberglass. Making it a good choice for multi-family buildings or for keeping the sound inside home theaters.

| STC | What can be heard at this level |

|---|---|

| 25 | Soft speech can be heard and understood |

| 30 | Normal speech can be heard and understood |

| 35 | Loud speech can be heard and understood |

| 40 | Loud speech can be heard, but not understood |

| 45 | The threshold at which privacy begins |

| 50 | Loud sounds can be heard, but are very faint |

| 60+ | At this level, good soundproofing begins. Neighbors generally are not disturbed by very loud speech from inside. |

Denim Insulation is Recyclable – Again

Denim insulation may be the only insulation that can be recycled again after being used. It can either be re-used as insulation batts or sent to be recycled into another product.

Denim Insulation Cons

As with most products, denim insulation is not perfect. Here are some of the cons you may find about these batts.

Denim Insulation Cost

Denim insulation costs at least 10% more than the equivalent fiberglass batt. In some cases denim costs twice as much as fiberglass. The discrepancy is due to availability, quantities, and raw material supply.

Denim insulation is a fairly new product. There are not a lot of manufacturers and some of those have shut down operations because of a lack of raw materials.

Denim Insulation Can be More Difficult to Fit

Insulation batts work best when they fit snugly into the stud cavity. Fiberglass batts are relatively easy to stretch an inch if needed. Or manipulate around pipes and wires. Denim is a tight mat that is not easily stretched. It is also more difficult to add a piece of denim where required.

Like almost all types of insulation, denim traps air inside the material to provide the R-value. Compressing the batts too much squeezes out the air–reducing performance.

Denim Is Harder to Cut

Denim batts are much denser than fiberglass, making them more difficult to cut. And cut straight. Heavy-duty shears or a utility knife with a heavy wide long blade (preferably at least 4”) usually work best. This YouTube video shows another cutting option that might work well for large projects.

Denim Insulation Requires a Vapor Barrier

Denim is very good at absorbing and holding moisture. If denim batts absorb too much moisture, the weight can cause them to slump inside the wall cavity. Wet insulation loses its insulation value. When used as batt insulation denim needs a vapor barrier such as 6 mil poly to keep it dry. Which adds to the cost and time.

Denim Insulation Can Be Difficult to Find

Not all building centers carry denim insulation. If they do, it may be the wrong size, or they may not have enough. Quite often you can only get it by special order which can lead to long waits. Or special orders may require minimum quantities.

Denim insulation is mostly restricted to wall and floor batts. Denim blown-in attic insulation is not available at this time. HVAC duct liner can be purchased but finding it may be a problem.

Why Denim Insulation Is Hard to Find

Denim jeans produce approximately 2.16 million tons of waste every year. Few countries possess the infrastructure or political will to collect and separate old clothing. Even the European Union–which has a system in place–only collects 35% – 50% for recycling.

Lack of collection, separating, and processing facilities chokes off the supply of denim insulation raw materials which means fewer manufacturing plants, less competition, and higher priced products.